How Railing Infill Panels can Save You Time, Stress, and Money.

Table of ContentsMore About Railing Infill PanelsRailing Infill Panels - TruthsRailing Infill Panels Can Be Fun For Anyone

Infill walls are usually mounted on website as private aspects that are pre-cut to length yet they can be pre-fabricated as large panels with the cladding currently affixed. The very same elements may be made use of for internal dividing wall surfaces, yet below the main issues are fire resistance and also acoustic insulation instead than resistance to.loading. A small inner pressure is made use of in the design of interior separating wall surfaces. @&&h2@ [top]

Kinds of

infill walling @&&/h2@ Different types of construction can be used to produce infill walls that cover between floorings in steel or concrete structures. Traditionally, infill walls used masonry or timber, yet the contemporary form of construction utilizes light steel C sections that span between the floorings as well as around openings. The C sections are placed at a normal spacing depending on the exterior faade products, and also at a spacing which is also compatible with basic plasterboard and sheathing board sizes. @&&h3@ [leading]

Not known Details About Railing Infill Panels

The light steel elements utilized in infill walls contains C areas and also U areas of. railing infill panels.

75 to 150 mm deepness that are chilly roll-formed from galvanized steel strip of 1. 2 mm density defined to BS EN 10346. The galvanizing( zinc layer) gives superb sturdiness. The C sections are placed at 400 or 600mm spacing and sets of C areas might be used alongside large openings. Wall panels can be pre-fabricated as storey-high systems or, more commonly, are site set up from C sections that are supplied cut-to-length. The second technique is usually the only solution in remodelling applications where tolerances in the original building and construction need to be accommodated. Site put together light steel walls in a steel mounted building Pre-fabricated light steel infill wall surface panels in a steel mounted structure Infill wall surfaces contain a lower' track' connected to the flooring and also a top' track' attached to the underside of the flooring above. This motion is important in concrete structures, where 2 to 3 mm shortening of the concrete structure per flooring can occur with time in addition to normal structural motions. The vertical C sections are made to cover 2. 4 to 5m in between floors, as well as to resist wind loads or various other lots in flexing. The horizontal C sections over and listed below the windows transfer lots back to the vertical C sections. A couple of layers of' fire-resistant' plasterboard( adapting BS EN 520, Type F) to the internal face attend to approximately 90 mins fire resistance to the light steel infill wall surface. @&&h3@ [top] Light steel dividing wall surfaces @&&/h3@ Pre-fabricated light steel wall surface panels Light steel separating wall surfaces make use of comparable components to.

See This Report about Railing Infill Panels

acoustic or fire functions and so are solitary leaf wall surfaces consisting of C sections of 55 to.

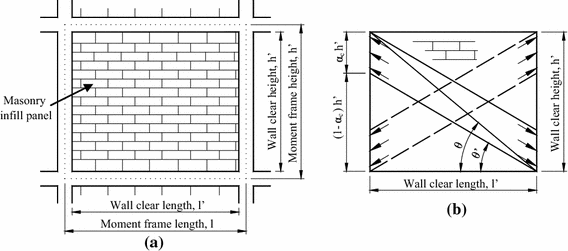

90mm deepness, depending on the wall elevation, with solitary layers of plasterboard on each side. @&&h3@ [leading] Stonework infill Related Site wall surfaces @ & &/ h3 @. Walls created from clay blocks or cinder block are the standard kind of infill wall surface building. Nevertheless, using block-work infill walls has actually decreased in recent times since it is an unpleasant and time consuming site procedure, and also calls for a large amount of products managing. From a design point of view, enhancing posts are needed beside large home window openings, as the masonry is not sufficiently strong to stand up to the high local wind lots alongside these openings. @&&h3@ [top] Concrete infill wall surfaces @&&/h3@ Pre-cast concrete infill wall panels Concrete infill walls are typically in the type of large precast concrete panels that are storey high and also often of a size determined by the column spacing. These large panels might be leading hung or bottom supported. They commonly bear onto the floor slab

using a boot plan, and are bolted back to the structure on the degree over or listed below. Important panels may be dressed in other products( usually concrete panels are clad in stone). Panel weights of roughly 300kg/m are normal, with panel sizes of in between 3 and also 9m and height of 3. 2m. The optimum size of panel is limited by transport considerations and also crane training capacity( both on site and also at the concrete works). 15 to 20 tonnes are regular optimum weights of precast concrete panels. @&&h3@ [top]. Timber mounted infill wall surfaces @&&/h3@ Timber infill wall surfaces utilize common wood why not find out more sections of 90.

and also 140mm deepness to span 2. 4 to 3. 6m between floorings and also are comparable in form to light steel infill walls. Wood sections are cut to size and also are placed at 400 mm or 600 mm spacing. The disadvantage of lumber in comparison to steel is that it is not as solid and it is not possible to use it in high wall surfaces or in walls with large openings. @&&h2@ [leading] Benefits of light steel infill as well as dividing walls @&&/h2@